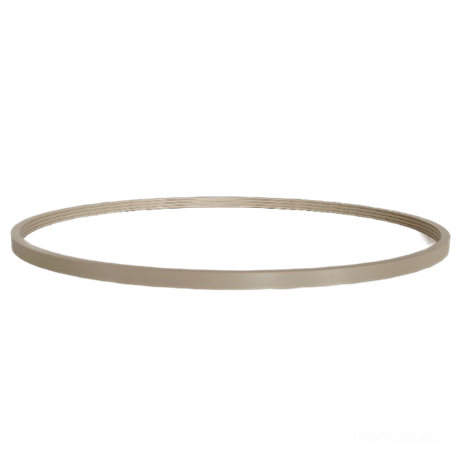

Dalian Luyang Technology PEEK Sealing Rings: A Superior Choice in the Oil Field

Dalian Luyang Technology's PEEK sealing rings have emerged as a paragon of high - performance components within the oil field domain. As a specialized high - performance engineering plastic product, the PEEK sealing retainer assumes a crucial role in the complex and demanding environment of the petroleum industry.

Mechanical Robustness for High - Pressure and High - Flow Conditions

The PEEK sealing rings exhibit remarkable mechanical properties. Their high strength and high modulus endow them with the ability to withstand substantial pressure exerted within valves and other critical components. In the oil field, where high - pressure and high - flow rate conditions are commonplace, these characteristics are essential. For instance, in subsea oil production systems, valves are often subjected to extreme pressures as oil is extracted from deep - sea reservoirs. The PEEK sealing retainer, with its robust mechanical structure, ensures that valves operate smoothly and maintain their integrity under such arduous conditions. Additionally, the good toughness of the PEEK material enables the sealing rings to resist impacts and vibrations, further enhancing the stable operation of equipment.

Wear Resistance and Friction - Reducing Traits for Enhanced Efficiency

The wear resistance of PEEK sealing rings is a key advantage in the oil field. The constant flow of oil, along with any suspended particles, can cause significant wear to equipment components over time. However, the PEEK sealing rings are highly resistant to such abrasion. Their low friction coefficient also plays a pivotal role. In pumps and valves, a lower friction coefficient means less energy is wasted in overcoming resistance, thereby improving the overall operating efficiency of the equipment. This not only extends the service life of the equipment but also reduces maintenance costs, as there is less need for frequent replacements due to wear - related failures.

Chemical Stability and High - Temperature Resistance in Harsh Petrochemical Environments

In the petrochemical industry, where corrosive media and high - temperature environments are the norm, the chemical stability and high - temperature resistance of PEEK sealing rings shine. These sealing rings can endure exposure to a wide range of corrosive substances, including various acids, alkalis, and hydrocarbons commonly found in oil and gas processing. In refineries, for example, where crude oil is processed into various products, the PEEK sealing rings maintain their integrity in the presence of corrosive chemicals used in the refining process. Their ability to withstand high temperatures, with a long - term use temperature reaching up to 260℃, makes them suitable for applications such as in the hot sections of furnaces and reactors, where traditional sealing materials would quickly degrade.

Aplikasi Serbaguna dalam Peralatan Petrokimia

Cincin pengedap PEEK digunakan secara meluas dalam sambungan saluran paip petrokimia, injap dan pam. Sebagai pengedap dan gasket, ia membentuk penghalang yang ketat, dengan berkesan menghalang kebocoran. Dalam sambungan saluran paip, walaupun sedikit kebocoran boleh menyebabkan kehilangan besar sumber minyak dan gas yang berharga, serta potensi bahaya alam sekitar. Cincin pengedap PEEK, dengan prestasi pengedap yang boleh dipercayai, memastikan saluran paip beroperasi tanpa kebocoran, meningkatkan kebolehpercayaan keseluruhan rangkaian pengangkutan. Dalam injap dan pam, ia memainkan peranan penting dalam mengekalkan fungsi peralatan ini dengan betul dengan menghalang cecair keluar, yang penting untuk operasi dan keselamatan yang cekap. Kebolehsuaian mereka terhadap pelbagai persekitaran kerja yang keras menjadikan mereka komponen yang amat diperlukan dalam bidang minyak dan industri petrokimia, menyumbang kepada operasi lancar proses perindustrian yang kompleks.